Our beer specialities

In former times almost every innkeeper used to brew his own beer. Depending on the quality and quantity of the hops, the malt and especially the hardness of the brewing water, typical local beers were produced. These beers had one thing in common: they were all unfiltered.

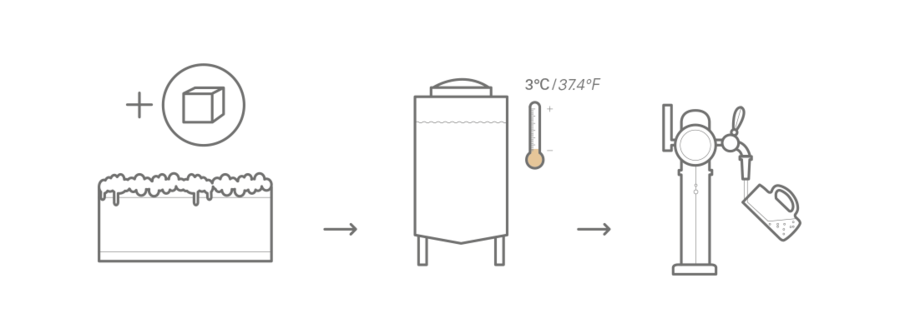

After the fermentation in the fermenting cellar, the liquid is loaded into one a storage tank for secondary fermentation. After 6 to 8 weeks at a temperature of 0 to 1 degree Celsius, the beer has reached maturity and can be enjoyed freshly tapped at the Schlossbräu Mariakirchen.

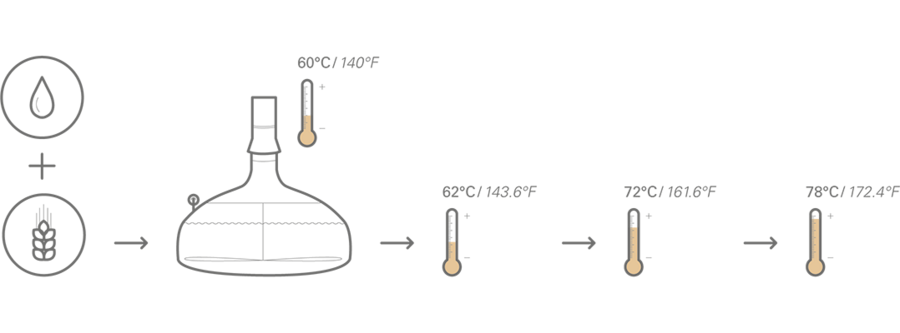

Step 1: “Mash vat”

Water is heated to 140° F in the mash vat and milled barley malt is added. The mash is heated in stages, breaking down the starches in the malt into fermentable sugars. This creates the typical character of the beer.

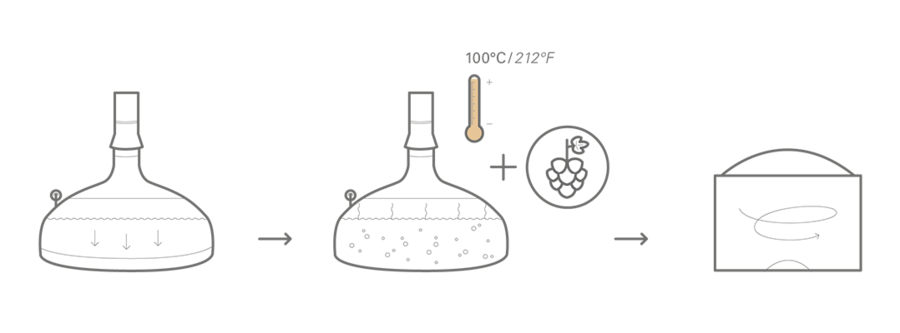

Step 2: “Straining vat, Wort vat and Whirlpool”

The mash is then put into the straining vat where heavy, nonsoluble elements settle. A natural filter layer is formed. Afterwards, the so-called wort is collected in a wort vat and boiled at 212° F. Hops are added at the beginning and shortly before the end of boiling. The quantity of hops determines the bitterness of the beer. After boiling, the beer is pumped into the whirlpool where the vortex separates heavy elements.

Step 3: “Fermenter, Storage tank, Serving”

Now the wort is conveyed to the fermentation tank and yeast is added. This is where the main fermentation occurs over a 6 to 7 day period. The beer matures in the storage tank at 37.4° F degrees for a further 3 to 5 weeks. The entire production process until serving takes 6 to 8 weeks.